For Customers, Users and Partners.

How to sanitize microscope incubators, thermal plates and gas mixers

In the European Centre for Disease Prevention and Control guidance for environmental cleaning in non-healthcare facilities, it is reported that a solution with a 70% concentration of ethyl alcohol is effective against two coronaviruses types (mouse hepatitis virus and transmissible gastroenteritis virus) when it is applied for one minute on the surfaces. These guidelines are in line with standard OKOLAB cleaning recommendations.

Here is a brief reminder for general cleaning recommendations of OKOLAB products:

For more detailed information, please refer to the Cleaning paragraph of the User Manual.

Introducing a new series of posts named #challengeaccepted to thank our marvel-ous R&D team for their outstanding design, innovation, customization and engineering capabilities.

Introducing a new series of post: #challengeaccepted.

On occasion of the upcoming Thanksgiving day, we're glad to start a new series of posts named #challengeaccepted to thank our marvel-ous R&D team for their outstanding design, innovation, customization and engineering capabilities.

Thanks to them, over the years Okolab has been able to not only drive innovation in the field of microscope incubation for live cell imaging and ICSI applications, but also to carry out in a timely manner new demanding B2B projects and to satisfy the most challenging inquiries of customized products for end-users.

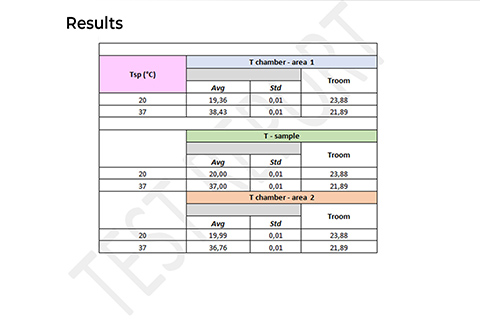

In this post we present the request to develop a top stage incubator able to provide a thermal stability within 0.01°C (yes, one hundredth of a degree) on the sample, contained into a 100 microns diameter capillary.

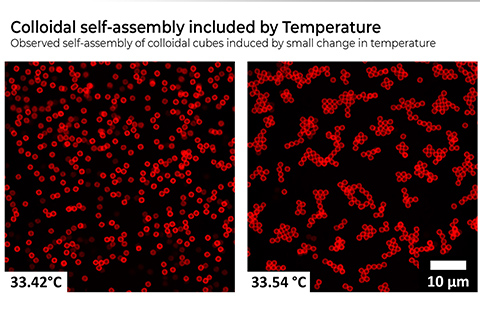

The application was to observe self-assembly of colloidal cubes induced by very small change in temperature.

The project took 3 months including manufacturing and delivery, and it involved four persons, one project manager who conceived and designed such a challenging system, one mechanical engineer for hardware design, one software engineer to implement dedicated control logics and to change readings resolution on our controllers, and one chemical engineer to test and assess performance. In addition, another person from our post-sale technical support helped the end-user to get the best from our system after the installation.

Among other unique design and engineering features, reaching the goal has required to base the thermal control algorithm on the simultaneous monitoring and inter-communication of temperatures in three different areas of this custom system.

This exciting request came from Dr. Janne-Mieke Meijer at Eindhoven University of Technology and the system has been sold on a Nikon confocal microscope. Many thanks to Dr. Chris Kennedy for providing the colloidal cubes' image that he captured.

COPYRIGHT © OKOLAB S.R.L. ALL RIGHT RESERVED. CERTIFIED ISO 9001.